How to choose carbide tool inserts and metal lathe inserts?

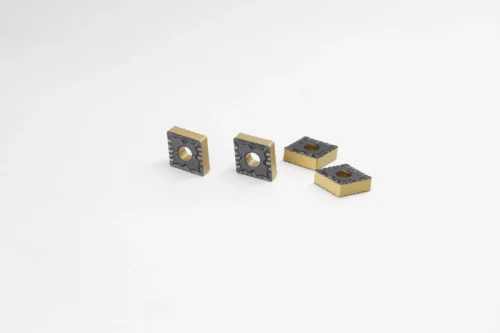

In the field of machining, carbide tool inserts and metal lathe inserts are the core tools to improve efficiency.

With their strong wear resistance and high temperature resistance, they can easily meet the cutting needs of materials such as steel, cast iron, and stainless steel.

But for friends who are new to the industry, facing a variety of models and parameters, choosing the right blade may be a headache. Don’t worry, we will recommend practical models and analyze the applicable scenarios for you in easy-to-understand language.

一、 Cemented carbide tool inserts: the “master key” for multi-scenario processing

Cemented carbide tool inserts are made of tungsten-cobalt alloy sintered under high pressure, which can maintain a sharp edge and withstand severe friction. We recommend the following three cost-effective models according to the processing type:

1. Kennametal KCU25 (turning insert)

Applicable machine tools: CNC lathes, ordinary lathes

Processing materials: stainless steel, alloy steel

Advantages: The unique chip breaker design can effectively control the shape of iron chips and avoid wrapping around the tool, which is particularly suitable for processing long-chip materials.

2. Sandvik GC4325 (milling insert)

Applicable machine tools: vertical machining center, gantry milling machine

Processing materials: carbon steel, mold steel

Advantages: Coating technology increases the life of the blade by 30%, and the single feed amount can reach 5mm during rough processing, doubling the efficiency.

3. Mitsubishi VP15TF (cut-off blade)

Applicable machine tools: automatic lathe, Swiss-type lathe

Processing materials: titanium alloy, high-temperature alloy Our salary is the same

Advantages: Ultra-thin 0.2mm cutting edge reduces material waste, and can be used with anti-vibration tool bar to process precision aerospace parts.

二. Metal lathe inserts: specially designed for turning

Metal turning requires higher precision of the inserts, and good metal turning inserts (Lathe tool inserts for metalworking) can directly determine the surface finish. The following three models are worth paying attention to:

1. Puwei CNMG120404 (external turning)

Applicable scenarios: batch processing of automotive shaft parts

Geometric features: 80° diamond tip angle balances strength and flexibility, Ra1.6 surface roughness can save grinding process.

2. Puwei 16ER11BSPT (thread turning)

Special design: full tooth profile ensures thread accuracy, and the error is less than 0.01mm when processing 60° metric threads.

Measured data: When processing 45# steel screws, the life of a single blade reaches 120 pieces, which is 40% more than ordinary blades.

3. Puwei TNMG-TSF (finishing turning blade)

Super finishing: CVD coating + mirror edge treatment, can achieve Ra0.8 mirror effect, directly turning hydraulic valve core without polishing.

三. FAQ

Q: Can the same blade process different materials?

A: Some general-purpose blades (such as TNMG331-MF3) can take into account both steel and cast iron by adjusting the cutting parameters, but professional blades (such as K10 material for cast iron) are more effective.

Q: How to solve blade chipping?

A: First check whether the clamping is loose, and then confirm whether the feed rate exceeds the standard. CBN blades must be used for processing hardened steel (HRC50 or above).