Resharpening Carbide End Mills Question:

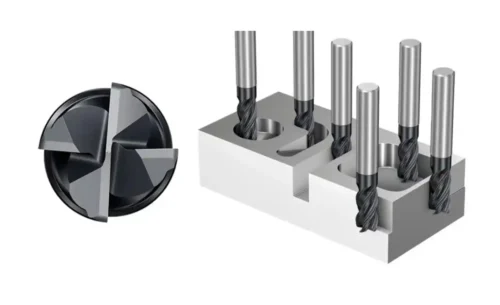

Carbide end mills are indispensable and efficient cutting tools in CNC milling machines and machining centers.

However, in the modern machining field of CNC milling cutter with the increase of processing tasks, the wear problem of end milling cutter has gradually become the focus of attention of many enterprises.

We can answer yes to the question of whether we can regrind Carbide end cutters.

Hard alloy end mills can be reground. Please provide some tips.

How often can one regrind carbide end mills

Although the hardness of cemented carbide material is extremely high, professional sharpening equipment and technology can effectively regrind it.

After resharpening, end mills can restore their sharpness and continue to be used for machining tasks, thus extending the service life of the tool and reducing the production cost of the enterprise.

However, resharpening end mills requires attention to the following points:

1. Select the appropriate sharpening equipment: professional sharpening equipment can ensure the cutting edge precision and surface quality of the tool.

2. Control the amount of resharpening: Excessive resharpening may lead to a reduction in the size of the tool and affect its machining performance.

3. Maintain tool integrity: the regrinding process should avoid damage to the structure of the tool to ensure its rigidity and cutting stability.

The importance of CNC end mill sharpening:

Carbide end milling cutter in the use of the process will be due to wear and tear leading to a decline in cutting performance, through sharpening can restore its sharpness, extend the service life and reduce tool replacement costs.

Advantages of CNC end mill sharpening:

1. Economy: Sharpening the end milling cutter can restore it to close to the performance of new products. The cost is much lower than purchasing new tools.

2. Environmental protection: reduce the waste of used tools, in line with the concept of sustainable development.

Summarize:

Carbide end cutters can be sharpened, but need professional equipment and technical support. Sharpening of CNC milling cutter can not only prolong the service life of the tool, but also reduce the production cost, and at the same time meet the requirements of environmental protection.

If the enterprise does not have the ability to sharpen, you can seek the support of professional tool manufacturers or recycling companies.

Puwei has been committed to producing, researching and developing cutting tools, CNC end mills and other materials.

We manufacture high – quality raw materials. If you are interested, please leave us a message. We will contact you within 24 hours.